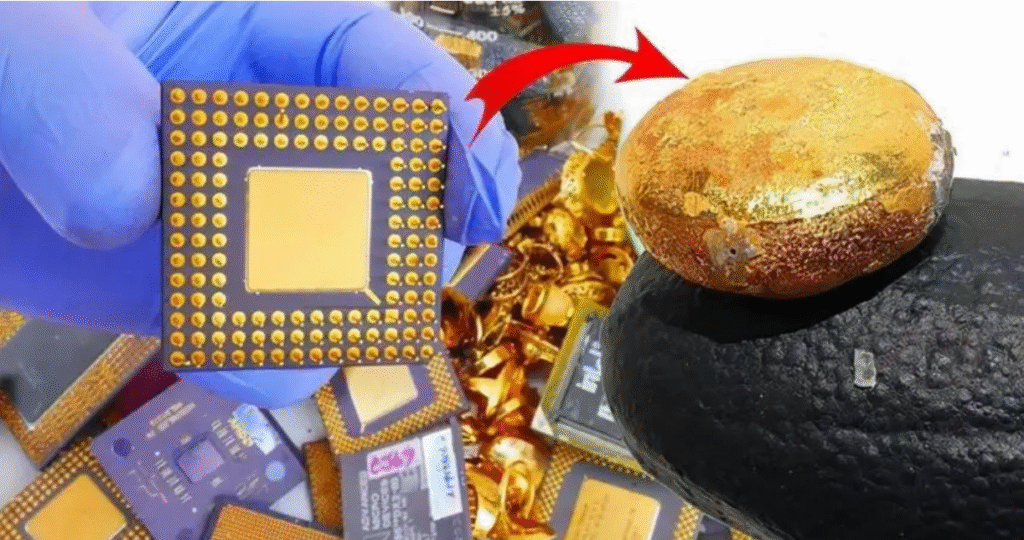

This guide outlines a standardized gold extraction protocol using aqua regia dissolution and reduction methods, optimized for clarity and operational efficiency.

Step 1: Dissolution of Impure Gold

- Objective: Solubilize gold from ore using aqua regia.

- Conditions:

- Conduct in a well-ventilated fume hood (critical for safety).

- Mix 3 parts hydrochloric acid (HCl) and 1 part nitric acid (HNO₃) to form aqua regia.

- Procedure:

- Place impure gold in a beaker; add aqua regia slowly to control exothermic reaction.

- After reaction subsides, heat the mixture to evaporate until ~1/5 of original volume remains (ensures complete dissolution).

- Add concentrated HCl in 3–4 aliquots (max amount = nitric acid in aqua regia) to expel free nitric acid (stop when no reddish-brown NO₂ gas evolves).

- Cool, filter to remove insoluble solids, and dilute with distilled water to ~50 g/L gold concentration.

Step 2: Gold Reduction (Precipitation)

- Objective: Convert dissolved gold ions (Au³⁺) to elemental gold (Au⁰).

- Conditions:

- Maintain solution temperature at 30–40°C.

- Use 150 g/L sodium bisulfite (NaHSO₃) solution as reducing agent.

- Procedure:

- Stir solution vigorously while rapidly adding NaHSO₃ until:

- Gold powder fully precipitates (solution becomes colorless and clear).

- pH is neutralized (test with pH paper; match local water pH).

- Decant supernatant; wash precipitated gold with boiling water until washings are colorless.

- Stir solution vigorously while rapidly adding NaHSO₃ until:

Step 3: Purification of Gold Powder

- Objective: Remove adsorbed impurities (e.g., iron compounds).

- Procedure:

- Stir gold powder with 15% hydrochloric acid for 5 minutes to dissolve contaminants.

- Decant acid carefully (avoid losing gold); repeat washing until effluent is colorless.

- Filter residue to obtain sponge gold (high-purity intermediate).

Step 4: Smelting to Refined Gold

- Objective: Convert sponge gold to 99.9% pure gold via smelting.

- Conditions:

- Use a crucible with borax (flux) to remove oxides.

- Heat with a musket furnace (or equivalent high-temperature source).

- Outcome: Solid gold ingot with ≥99.9% purity.

Essential Chemicals and Tools for Gold Extraction

| Category | Reagents/Tools | Role |

|---|---|---|

| Dissolution | Nitric acid (HNO₃), hydrochloric acid (HCl), aqua regia | Dissolve gold; form chloroauric acid complex (HAuCl₄). |

| Reduction | Sodium bisulfite (NaHSO₃), zinc strips (alternative) | Reduce Au³⁺ to Au⁰; precipitate gold powder. |

| Purification | Hydrochloric acid (15%), borax (Na₂B₄O₇·10H₂O) | Remove iron/metal impurities; flux for smelting. |

| Safety & Handling | Gas mask, acid-resistant gloves, fume hood, pH test paper | Ensure operator safety; monitor solution conditions. |

| Smelting | Crucible, musket furnace, sodium carbonate (Na₂CO₃) | High-temperature melting; stabilize molten |

For bulk procurement of reagents (e.g., nitric acid, sodium bisulfite) or specialized equipment, reach out to our team for tailored mining solutions.