The Mongolian 5,000 t/d Gold Heap Leaching Project Utilizes Environmentally Friendly Reagent A+, Saving Costs, Protecting the Environment, and Achieving Satisfactory Leaching Rates

The Mongolian client approached DasenMining through an introduction, looking for a turnkey gold concentrator project. After comprehensive consultations, DasenMining presented a complete construction engineering design solution involving:

- Process engineering

- Civil engineering

- Electrical engineering

- Water supply and drainage

- Heating systems

The client was particularly impressed by DasenMining’s efficient, low-consumption electrolysis system, which significantly accelerates project timelines and reduces operational costs. This led to the signing of a cooperation agreement to jointly develop the gold concentrator project.

Gold Heap Leaching Process Flow

The project adopted a modern heap leaching and refining process:

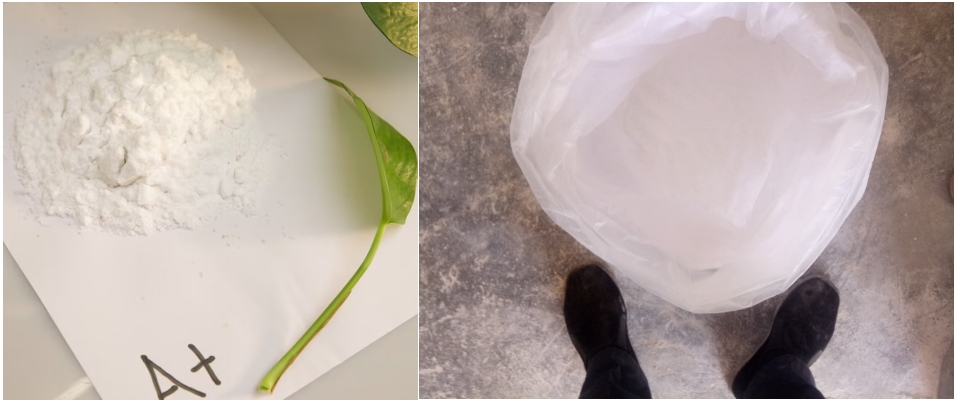

- Heap Leaching – Application of environmentally friendly reagent A+ for dissolving gold from ore.

- Adsorption – Gold ion capture using activated carbon.

- Desorption & Electrolysis – Gold recovery through DasenMining’s high-efficiency electrolysis system.

- Activated Carbon Pickling & Regeneration – Ensuring carbon reusability and stability.

- Metallurgy – Final gold smelting to produce high-grade bullion.

Process Specifications and Performance

Traditional sodium cyanide, though effective, poses serious challenges due to volatility, toxicity, and associated explosion risks. To address safety and environmental concerns, the project implemented:

- Environmentally Friendly Reagent A+:

- Achieved a gold recovery rate of 79%.

- Ensured safer on-site handling compared to sodium cyanide.

- Provided excellent leaching results with reduced ecological risks.

- DasenMining Electrolysis System:

- Delivered high-efficiency gold recovery with low energy consumption.

- Shortened production cycle by over 20 hours compared to conventional systems.

- Received unanimous praise from on-site teams.

Client Feedback

After experiencing the technical discussions and the trial phase, the client highlighted three major advantages of DasenMining’s equipment and reagent A+:

- Sustainability – Reduced environmental footprint compared to cyanide-based leaching.

- Efficiency – Higher recovery rates and shorter processing times.

- Cost-effectiveness – Optimization of operational costs without compromising safety.

The successful delivery of the Mongolian gold heap leaching project further strengthens DasenMining’s reputation as a reliable partner in green metallurgy and modern mineral processing solutions.

The adoption of environment-friendly reagent A+ in the Mongolian 5,000 t/d gold heap leaching project demonstrates how technology innovation can align efficiency and environmental protection. By integrating reagent A+ with DasenMining’s advanced electrolysis system, the project achieved:

- Safe and green operations

- High gold recovery rates (79%)

- Significant time and cost savings

As the global mining industry continues transitioning toward sustainable practices, solutions like A+ reagent and DasenMining’s turnkey engineering expertise will play a pivotal role in shaping the future of gold extraction.