Granulation and Stacking

1. Granulation Process

Proper granulation is essential for efficient gold leaching. The following parameters must be controlled:

pH Adjustment with Lime

- The pH of the ore-lime mixture must be between 9.5 and 10.5.

- To determine the correct lime dosage:

- Prepare samples in beakers using 1000 grams of ore.

- Add 2g, 4g, and 6g of lime to separate samples.

- Add water to form aggregates.

- Let the samples sit for 24 hours, then measure the pH.

- Select the mixture with a stable pH in the desired range.

Cement Testing (Aggregate Stability)

- Mix ore, lime, and a small amount of cement.

- After 24 hours in water, aggregates should not turn into mud.

- If aggregates remain intact, the lime dosage is sufficient.

Sodium Cyanide (NaCN) Dosage

- NaCN concentration: 0.1% to 0.5%.

- Dosage: 60 to 150 grams per ton of ore, depending on ore impurities and moisture.

- Final pH of granules: Around 11.5.

Moisture Content

- Granule moisture: 15% to 20%.

- Ore moisture: Approximately 10%.

- Total moisture must not exceed 30%, or granules may soften and break down.

Curing Time and Weather Considerations

- Curing time: At least 72 hours.

- If it rains during granulation:

- Cover the ore to prevent gold loss.

- Alternatively, use side-building and side-spraying to protect against weather during granulation.

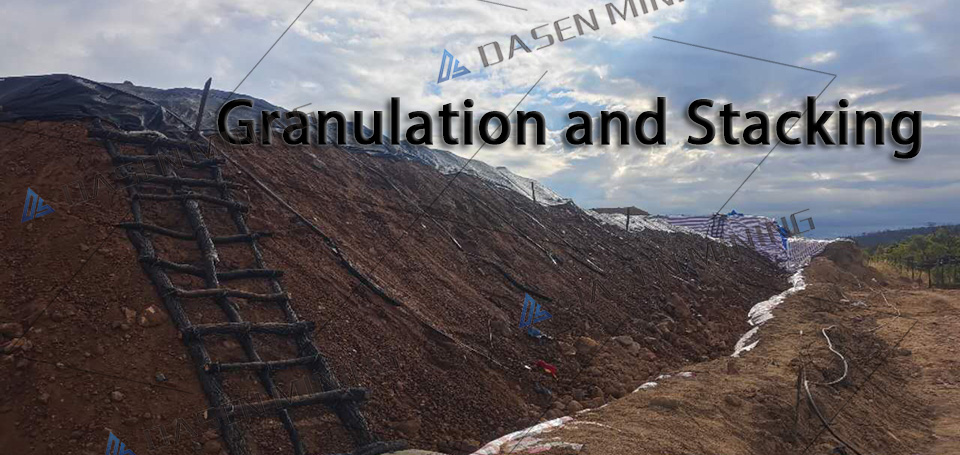

2. Ore Stacking

Stacking affects permeability and leaching efficiency.

- Avoid excessive compaction; rolling the heap repeatedly can crush particles into dense “cakes.”

- Use conveyor belts when possible for even distribution.

- Recommended heap height: 3 to 4 meters.

- Proper stacking improves leaching rates over time.

You can learn more about several technical aspects of heap leaching by following us

or cantact :Whatsapp:+8613319277356

Email: chemicals@oremagnetic.com