Global Lithium Resource Landscape

The global lithium resource landscape includes over 150 identified lithium minerals and lithium-bearing minerals, of which more than 20 are commercially significant.

Understanding the chemical composition—especially lithium oxide (Li₂O) content and associated elements—is essential for evaluating deposit quality, beneficiation potential, and economic viability.

| Mineral | Lithium Oxide (%) | Associated Elements (%) | Economic Significance |

|---|---|---|---|

| Lithium Beryllite | 23.4–25.4 | — | High-grade lithium source, often linked to beryllium |

| Spodumene | 5.8–8.1 | Rubidium (1.51–3.80), Cesium (0.02–1.082) | Core hard-rock lithium mineral for battery supply |

| Lepidolite | 3.2–6.45 | Rubidium (0.002–0.007), Cesium (0.002–0.008) | Common in pegmatites; often processed for lithium |

| Lithium Phosphate Aluminum | 7.1–10.1 | — | Specialized phosphate lithium mineral |

| Lithium Feldspar | 2.9–4.8 | — | Used in glass/ceramics; secondary lithium source |

| Iron Lepidolite | 1.1–5.0 | Rubidium (1.22–2.05), Cesium (0.02–0.22) | Lower-grade lithium with rubidium/cesium by-values |

| Clay Lithium Ore | Variable | Typically associated with aluminum/iron clays |

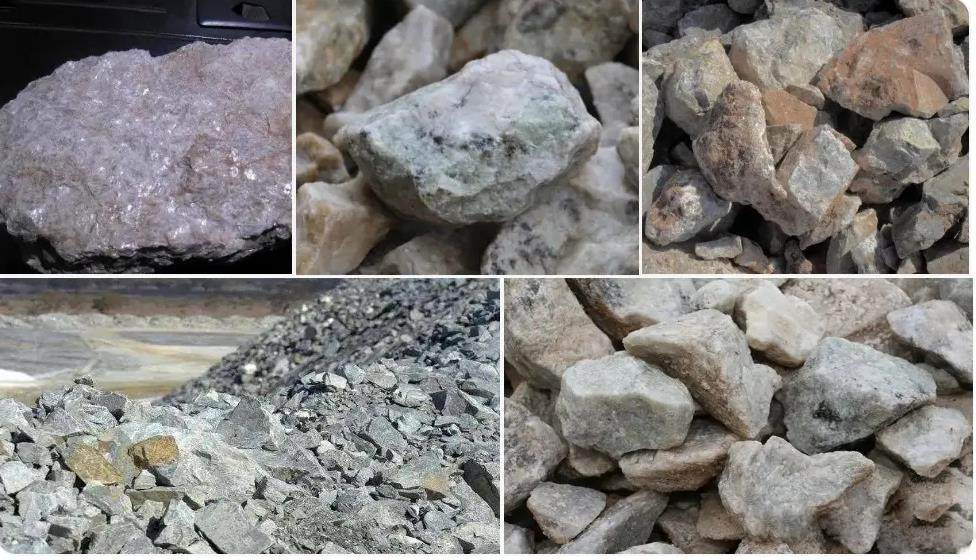

Hard-Rock Lithium Deposits (Spodumene, Lepidolite, Petalite)

Associated Elements:

Niobium (Nb), tantalum (Ta), beryllium (Be), rubidium (Rb), cesium (Cs), mica, feldspar, and fluorite are commonly found alongside hard-rock lithium ores.

Opportunities:

- Rubidium and cesium, used in electronics, aerospace, and specialty chemistry, can enhance project profitability when recovered as by-products.

- Tantalum and niobium may be extracted through advanced gravity or magnetic separation circuits.

Challenges:

- Mica and feldspar often act as gangue minerals, requiring optimized beneficiation (e.g., flotation, gravity separation) to maximize spodumene recovery and grade.

Salt Lake (Brine) Lithium Deposits

Associated Minerals:

Sodium (Na), potassium (K), magnesium (Mg), sulfate, trona, boron (B), bromine (Br), and iodine (I) frequently coexist in brine systems.

Opportunities:

- Potassium and boron can be co-produced to offset lithium extraction costs.

- Emerging technologies now allow commercial bromine and iodine recovery, further enhancing resource value.

Challenges:

- Complex brine chemistry complicates selective lithium recovery.

- Sophisticated separation methods (e.g., solvent extraction, ion exchange, membrane separation) are required to achieve high lithium purity.

Strategic Considerations for Lithium Project Development

Pre-Feasibility Studies:

Comprehensive multi‑element assays during exploration stage help identify all valuable co-elements present in the ore or brine.

Processing Integration:

Develop flowsheets that recover both lithium and co-products—for example, solvent extraction for bromine from brines or magnetic separation to capture niobium and tantalum from pegmatite ores.

Environmental and Regulatory Compliance:

Proper management of associated compounds (e.g., fluorite, boron) ensures compliance with local environmental regulations and prevents operational delays.

Actionable Insights for Global Miners

- Diversify Revenue Streams:

Treat associated elements as strategic co-products rather than waste. For example, rubidium from lepidolite can command premium prices in the high-tech chemical market. - Collaborate with Process Experts:

Work with experienced mineral processing and engineering firms to tailor extraction technologies and maximize recovery efficiency for complex ore compositions. - Monitor Market Trends:

Global demand for by-products—such as cesium for atomic clocks and bromine for flame retardants—is expected to grow. Integrating these markets into project planning future‑proofs economic performance.

Comprehensive deposit evaluation and integrated flowsheet design are fundamental to unlocking the full potential of lithium resources.

By recognizing and recovering valuable co-existing minerals, mining companies can:

Increase profitability,

Improve resource utilization, and

Enhance sustainability in the expanding global lithium supply chain.